- Home

- News

- New High-tech Research and Development| Intelligent X-ray Inspection for Oil Leakage Caused by Lax Sealing and Packing with Products in Sealing Mouth

New High-tech Research and Development| Intelligent X-ray Inspection for Oil Leakage Caused by Lax Sealing and Packing with Products in Sealing Mouth

New High-tech Research and Development| Intelligent X-ray Inspection for Oil Leakage Caused by Lax Sealing and Packing with Products in Sealing Mouth

The phenomena of lax sealing and packing with products in sealing mouth are the top major stubborn diseases in leisure food processing, which will result in products “oil leakage”, and then the oil will flow into the subsequent production line to form pollution and even lead to the result that the packing food deteriorates in short time.

Breaking through the technical barriers, Shanghai Techik has launched the intelligent X-ray Inspection System which is equipped with new intelligent identification technology to directly hit customer pain points and solve the pending problems of packing with products in sealing mouth and oil leakage packing. The unprecedented technological innovation is of milestone significance.

Relying on Techik TIMA platform, the Intelligent X-ray Inspection System for oil leakage packing and packing with products in sealing mouth is lean and standardized to solve the compliance inspection problems in an all-round way.

The X-ray Inspection machine will debut at the Shanghai International Food Processing and Packaging Machinery Exhibition (PROPAK) from June 23-25,2021. Welcome to have a visit to the exhibition at that time.

IMPORTANT

The Birth of Intelligent X-ray Inspection System for Oil Leakage Caused by Lax Sealing and Packing with Products in Sealing Mouth

In 2021, inheriting the brilliant achievements of sales growth in 2020, Shanghai Techik keeps pace with The Times and responds to the call of technological innovation during the 14th Five-Year Plan: intelligent manufacturing entered the fast track and opened a new situation:

The new-launched machine can not only detect foreign bodies, but also can detect package problems such as oil leakage caused by lax sealing, and packing with products in sealing mouth, and product weight. Shanghai Techik strives to solve practical problems for customers, to escort the quality and safety of products, which is the Gospel of food production enterprises.

TXR-B3-4010 Series

Characteristic with intelligence, high speed, high-definition and high precision, the new-developed Intelligent X-ray Inspection System for oil leakage and packing with products in sealing mouth is armed with the following technical highlights.

PART ONE: Contaminants Inspection

Comprehensive detection of tiny metal, non-metal foreign bodies and pollutants in the packaging

Such as: metal, glass, stones and other malignant impurities, plastic sheets, mud blocks, tie bands and other low-density pollutants

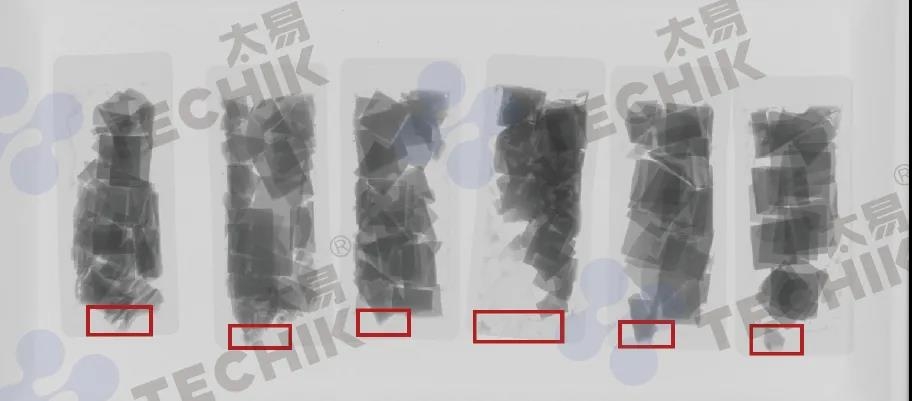

▼PART TWO: Oil Leakage Packing & Packing with Products in Sealing Mouth Inspection

Adopt a high-speed HD TDI technology detector

Exposure is eight times as traditional detectors

Packing quality of oil-contained products and bulk products can be accurately detected and the unqualified ones can be effectively rejected.

Unqualified packing includes: Oil leakage packing, packing with products in the sealing, and oil and juice pollution

Packing with products in the sealing mouth, contaminants, under weight, oil leakage

▼PART THREE: Providing flexible solutions

Customized, exclusive and perfect solutions according to the customer’s needs. For example:

Detecting machine customization for oil or bulk fillers

Corresponding inspecting scheme can be selected according to the volume of large, medium and small bags

Air blow or flipper can be selected according to the product

Orderly or disorderly parallel processing of multiple products can be detected

More prominent intelligent effect

▼PART FOUR: Visual Inspection

Built-in futuristic technology —- ”Intelligent Vision” visual inspection system independently developed by Techik

Quality compliance inspection for the appearance of product packaging

Such as: sealing folds, skewed sealing, oil stains, etc

To achieve the visual perfection

Assist in the brand construction of processing enterprises

▼PART FIVE: High-speed production line

Transfer belt speed of up to 120m/min

▼PART SIX: Accurate rejecting

The rejecter adopts 48 high-speed blow rejecting method as standard

Accurate rejecting for different packaging products

Even large-packaged products can still be accurately rejected

▼PART SEVEN: Online weighing

High-speed and high-precision weight compliance detection and precise rejecting

Detection accuracy is up to ± 2%

▼PART EIGHT: Techik unique TIMA platform

Intelligent X-ray Inspection System for oil leakage and packing for products in sealing mouth based on TIMA platform

Techik TIMA platform covers the whole cycle of production, R & D, design to after-sales

Comprehensive innovation of the research and development mechanism of detecting equipment

Create better-performance detecting equipment in a more efficient way

Advantages: high precision detection, low energy consumption and low radiation, modular structural design (operation and maintenance cost reduction), excellent image processing algorithm, high-level health design (cleaning trouble reduction), the appearance architecture of a sense of technology

Help food enterprises to maximize their benefits