- Home

- News

- Techik Dual-Energy X-ray Inspection System Solves Inspection Difficulty in Frozen Food and Meat Industry

Techik Dual-Energy X-ray Inspection System Solves Inspection Difficulty in Frozen Food and Meat Industry

Techik Dual-Energy X-ray Inspection System uses dual-energy technology, that is, low energy and high energy technology, in X-ray inspection industries, which breaks through technical difficulties in frozen food and meat industry.

Frozen Food X-ray Inspection

For frozen vegetables and fruit as well as dried vegetable and fruit, which is featured as similar density between the product and contaminants, Techik dual-energy X-ray inspection machine performs excellent.

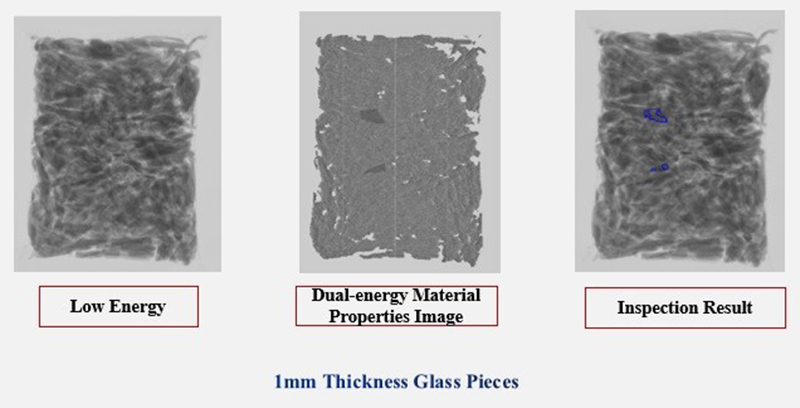

The following chart is the image of 1mm glass piece by dual-energy X-ray inspection machine

Meat Industry X-ray Inspection

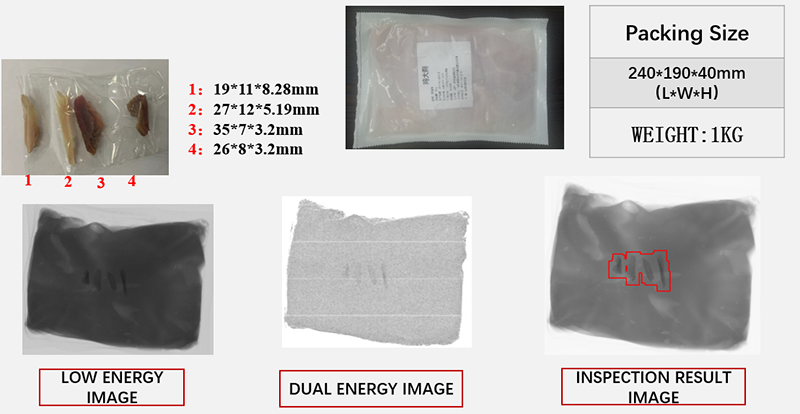

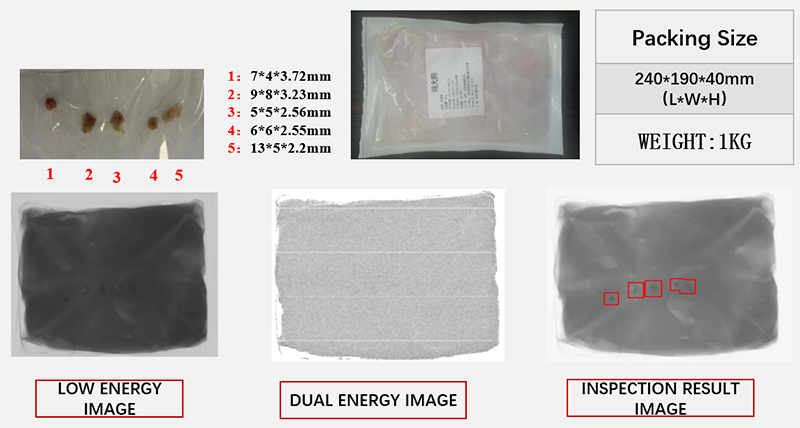

Main two applications of Techik Dual-Energy X-ray Inspection System:

First, hard bone inspection. The followings are inspection chart of different sizes hard bone.

Second, fat content inspection.

Techik Dual-Energy X-ray Inspection System obtains fat content about meat based on the the function relationship between the obtained eigenvalue R and the fat content of the meat sample and the eigenvalue R. The fat content inspection has the advantages of short detection time, high precision, simple data processing, low cost, and no damage to meat samples, and can realize large-scale online rapid detection.

What’s more. Techik Dual-Energy X-ray Inspection System has the following designs to guarantee the food sanitation.

1. Slope design to ensure no sewage residue

2. No hygienic dead corners, no bacterial breeding areas

3. Open design of the whole machine, can clean various corners

4. Modular design, the conveyor belt can be quickly disassembled for easy cleaning