Techik Intelligent Detection Enables Dairy Products Safer

From September 10 to 12, 2021, the 2021 China (International) Dairy Technology Expo was grandly held in Hangzhou International Expo Center, attracting a large number of professional visitors all over the world. This exhibition covers pasture construction, dairy raw materials, ingredients, processing, packaging, testing and other sections, providing a communication and business platform for the entire industry chain.

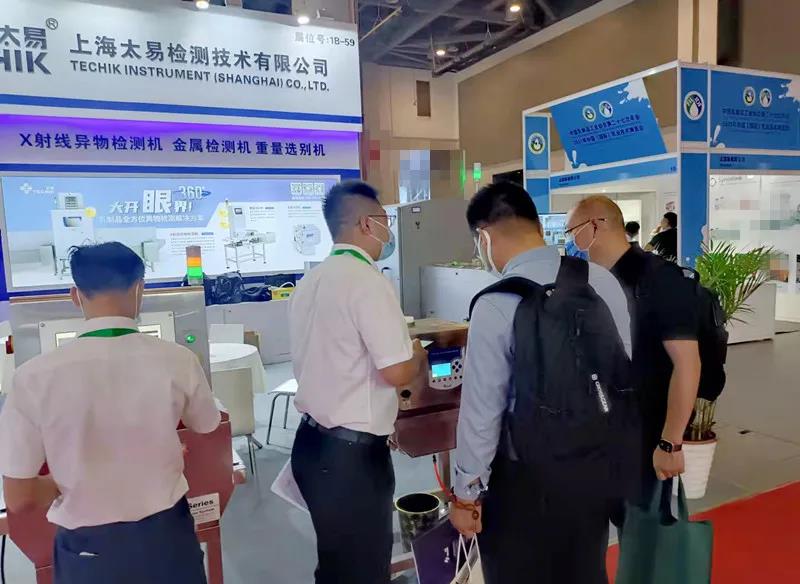

Shanghai Techik provides dairy products companies with detection equipment and system solutions at booth 1B-59 to help the high-quality development of the dairy industry and bring more consumers a healthier life.

In recent years, driven by factors such as consumption upgrades and technological progress, the low-temperature dairy industry has developed rapidly. Low-temperature dairy products are rich in nutrients but have a short shelf life. They usually use roof boxes, plastic bottles, plastic cups, plastic bowls and other low-temperature resistant packaging forms, of which vertical packaging accounts for a relatively high proportion.

For dairy products in vertical packaging such as bottles and cans, it is difficult to detect foreign objects on the top, bottom and other edge areas. Packaging designs such as irregular bottles and irregular lines also increase the detection difficulty. How to efficiently detect small foreign objects inside vertical packaging products in different areas? It is a very challenging subject.

The new generation of canned TXR-J series intelligent X-ray foreign body inspection machine displayed at Techik booth has a unique single-view source and three-view structure and the self-developed “Smart Vision Supercomputing” intelligent algorithm, which is committed to eliminating detection blind spots, 360°no dead corners to capture foreign objects in every corner of vertical packaging products. For small foreign objects in difficult-to-check areas such as irregular bottle bodies, bottle bottoms, screw mouths, tinplate cans pull rings, and press edges, the detection results are even more impressive.

In addition to higher detection accuracy, richer quality control functions, lower power consumption, more flexible smart production line solutions, etc., make Techik’s new generation of canned intelligent X-ray machines assist dairy companies in all aspects improve efficiency and strictly control product quality.

The high-speed, high-definition X-ray machine and the smart X-ray machine exhibited together can be adapted to the needs of different production lines, and carry out comprehensive intelligent detection of foreign matter, weighing, and missing dairy products in bags, boxes and other small and medium-sized packages.

The gravity fall metal detector suitable for powdered and granular dairy products not only optimizes the main board circuit parameters, but also greatly improves the detection accuracy and stability. The metal-free area is also reduced by about 60%. It can also be installed flexibly in a small space. Its compact appearance and powerful functions attract professional visitors to the booth for consultation. The standard weight sorting checkweigher with its excellent dynamic detection function and easy-to-use interactive interface, highly meets the needs of dairy companies for efficient and convenient sorting and weighing equipment.

Besides consulting the equipment in detail, the audience can also discuss the quality control of dairy products with professional technical teams and sales teams, and obtain targeted intelligent testing solutions. A full range of professional detection equipment and customized detection solutions have allowed Techik to gain recognition again and again.