- Home

- News

- TIMA platform, higher precision, 360 degree no dead angle detection; iron can, glass tank, shaped bottle, all can be done

TIMA platform, higher precision, 360 degree no dead angle detection; iron can, glass tank, shaped bottle, all can be done

From November 10 to 12, the 11th Shanghai International canned food, raw materials, machinery and equipment exhibition opened in Shanghai. 3800 exhibitors from 49 overseas countries and regions gathered in Shanghai New International Expo Center, opening a double experience journey of science and technology vision. In order to promote the overall improvement of the whole industry chain of canned food, Shanghai Techik provided foreign matter detection scheme for enterprises in the completely industrial chain of canned food at booth C15 of E7 Pavilion.

Stand-onstie

Stand-onstie

As one of the professional exhibitions of domestic canned food industry, Shanghai International can show covers the whole industry product categories, collects the latest products and technologies, and involves the whole industry chain. During the exhibition period, the 24th FHC Shanghai global food exhibition, the 13th fresh Asian fruit and vegetable industry expo, FHC China international culinary art competition and dessert baking competition will be held at the same time. The novel characteristic activities attracted a large number of professional visitors from all over the world, and the exhibition site burst out infinite vitality

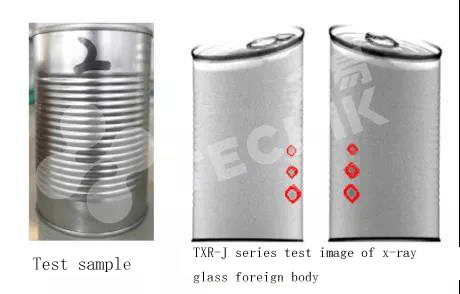

At ten o’clock in the morning, the crowd was surging at the scene of Shanghai Techik C15. As the booster of the next new growth point in the catering industry, the multi light source and multi perspective canned X-ray machine (currently the maximum is 3 light sources and 7 viewing angles) developed by Shanghai Techik can be applied to the detection of foreign matters in a variety of can packaging, such as iron cans, glass bottles, shaped bottles and other packaging types, with stable detection results and high accuracy.

Sales Manager of Shanghai Techik explains canned X-ray machine to customers

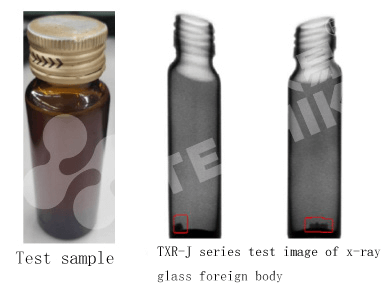

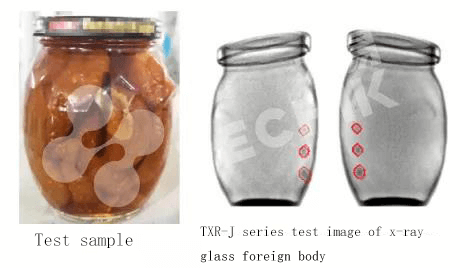

In addition to the material of the container will affect the detection effect, the shape of the container will also do. The special shape will make the impurities “hidden” somewhere in the container, which is difficult to detect. In addition, as the best container for fresh food, the glass bottle is most likely to burst during the cleaning process. At the same time, because the density of large and thin glass fragments is almost the same as the product density, it is generally the most difficult to detect. How to detect micro impurities in different positions to ensure 100% detection of harmful substances? It is a challenging subject.

Shanghai Techik’s R & D demonstrates canned X-ray machine for customers Sales Manager of Shanghai Techik provides canned food packaging solutions for customers

Shanghai Techik’s canned TXR series X-ray machine, relying on the TIMA platform of Techik company, adopts a new generation of high-definition imaging platform, greatly improving the detection accuracy; adopting multi-source and multi view angle design, eliminating the blind area, and combining with the intelligent recognition algorithm of the new generation TIMA platform, the high-precision 360 ° inspection without dead angle in the container is truly realized. It is particularly worth mentioning that the new generation of intelligent recognition algorithm of TIMA platform can still achieve very ideal detection results for abnormal bottles and thin pieces of foreign bodies!