What are the challenges in macadamia sorting?

Difficulties In Sorting Macadamia Nuts

Sorting macadamia nuts presents several unique challenges that can impact product quality and processing efficiency. Understanding these difficulties is essential for producers aiming to maintain high standards.

1. Shrinkage and Size Variation:

- Macadamia nuts often vary significantly in size and shape, complicating the establishment of uniform sorting criteria. Shrinkage can occur due to improper handling or storage conditions, leading to inconsistencies.

2. Color Variability:

- The color of macadamia nuts can change based on ripeness and storage conditions. Differentiating between perfectly ripe nuts and those affected by mildew or discoloration is crucial but challenging.

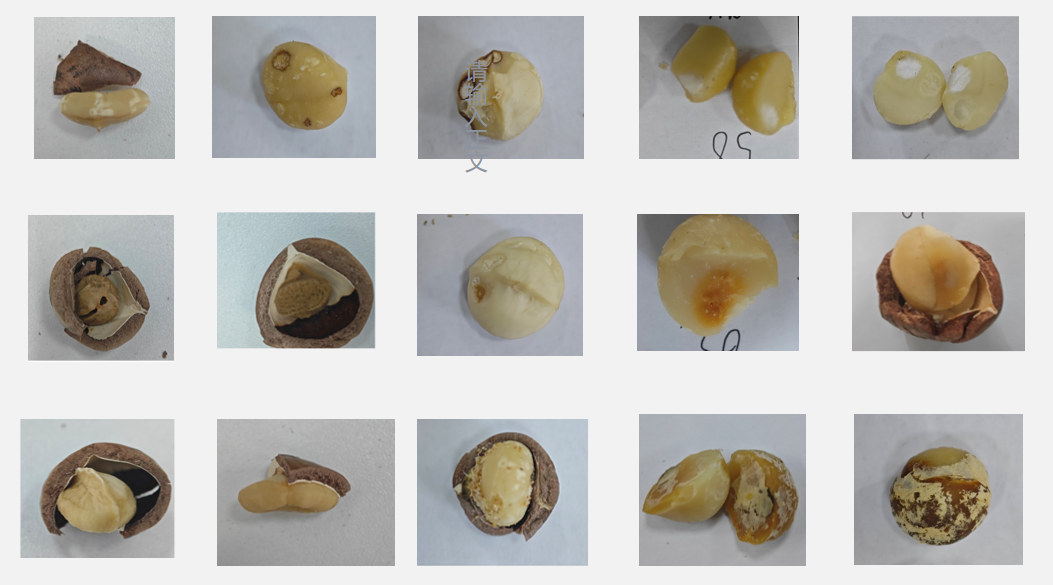

3. Surface Defects:

- Nuts may exhibit surface imperfections like insect bites or scratches, which can be difficult to detect without advanced imaging technology. These defects can adversely affect marketability.

4. Internal Defects:

- Identifying internal issues, such as hollow kernels or damaged nuts, poses a challenge. Non-destructive inspection methods are necessary to assess these qualities without compromising the product.

5. Foreign Contaminants:

- The presence of foreign materials, such as shells or debris, complicates the sorting process. Accurately identifying and removing these contaminants is vital for ensuring product safety.

How Techik Can Help

Techik offers innovative solutions designed to address the unique challenges of sorting macadamia nuts. Our advanced technologies ensure that producers can maintain high quality and efficiency throughout the sorting process.

1. X-Ray Inspection Systems:

- Techik’s X-Ray machines are capable of detecting internal and external defects without damaging the nuts. This technology identifies shrinkage, foreign objects, and internal quality issues, ensuring that only the best nuts are processed.

2. Color Sorting Machines:

- Our state-of-the-art color sorting machines utilize multi-spectral imaging to differentiate between healthy and defective nuts. By accurately detecting color variations, these machines can identify mildew-affected nuts and ensure uniformity in the final product.

3. Surface Defect Detection:

- With advanced imaging technology, Techik’s systems can spot surface defects, such as insect bites or scratches, ensuring that only high-quality nuts are selected for packaging.

4. Adaptability:

- Techik’s sorting solutions can be tailored to meet specific production needs, allowing for adjustments based on varying quality parameters. This flexibility enhances sorting accuracy and efficiency.

5. Increased Efficiency:

- By minimizing manual checks and human error, Techik’s automated systems improve overall productivity and reduce waste, helping producers maximize their yield and profitability.

In conclusion, sorting macadamia nuts presents numerous challenges that require advanced solutions. Techik’s cutting-edge inspection and sorting technologies effectively address these difficulties, ensuring that producers can deliver high-quality macadamia nuts to consumers while optimizing operational efficiency.