TXR series X-ray inspection for NUTS, especially for NUTS with wormhole and worm corpse

TXR-P series, X-ray for product in bulk 4080GP

The wormhole X-ray inspection machine (hereinafter referred to as the wormhole X-ray machine) continues the physics B-series integrated design in appearance, which can adapt to various production line docking, handling and movement, while being linear and smooth, with a sense of technology.

In terms of hardware, the Wormhole X-ray machine continues to use high-definition high-speed detectors, and the detection accuracy is improved by two levels. At the same time, the design of the split-slot conveyor belt structure effectively solves the accumulation and deviation of round and easy-rolling materials such as walnuts and macadamia nuts, ensuring uniform and consistent division of materials, and realizing identification that is more advanced, detection and rejection.

Introduced independently developed separation algorithm technology and depression detection technology, which can effectively identify wormholes, insect pests, scratches, and insect bodies. With optimized air rejection design, point-to-point precise rejection.

Core highlights

01 Separation algorithm technology

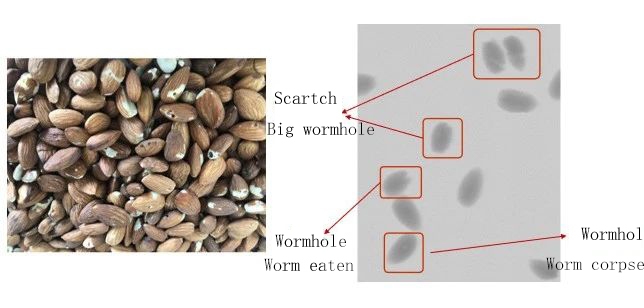

Compared with traditional equipment, the separation algorithm technology can make the nuts appear autonomously separated on the image of the X-ray machine, especially for materials with defective edges, to avoid wormholes and insects caused by the glued edges of the nuts. , Bugs, corpses, scratches, missed inspections, wrong inspections, etc., reducing the probability of false detections

Figure: The imaging effect of wormhole of almond be detected by the x-ray machine

02 Dent Detection technology

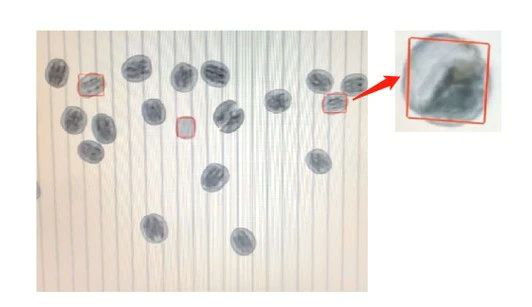

In addition to wormholes, worm corpses, shrinkage, mildew and shell are also major barriers in nut sorting industry. Dent detection technology can quickly identify whether mildew or atrophy occurs inside nuts through gray image, to eliminate them

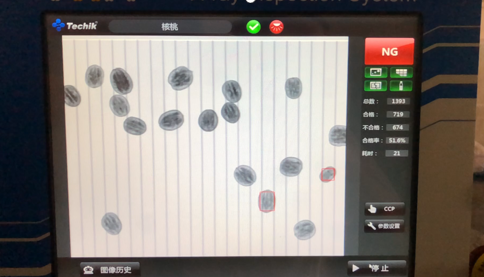

Figure: imaging effect of walnut detected by wormhole X-ray machine

Wormhole X-ray machine can be used to separate the bad materials such as wormhole, mildew, scratch, etc. at the same time, it can stack and separate glass, stone, plastic, straw and other foreign bodies. In addition, the wormhole X-ray machine can be customized according to the needs of customers to the greatest extent in line with the production line design of processing.

In the structural design, we continue to use the structural design of quick demolition and IP66 waterproof technology, which can be easily removed and cleaned within 2 minutes. Xing Bo, our chief technical engineer, said that food safety inspection is the last link of the food process line, which is the most easily overlooked but also the most important link. The wormhole X-ray machine is a high-efficiency solution for the three “mountains” of the nut industry of Shanghai Techik, namely, wormhole, worm corpse.