What can Techik food X-ray inspection machine do?

An X-ray inspection system, non-destructive inspection, can be used to inspect internal structures and defects that are not visible from the outside, without destroying the object. That is, Techik food X-ray inspection machine can identify and reject the foreign bodies and product defects in various food such as nuts, meat, seafood, vegetables, fruit, snack food, seasoning and etc.

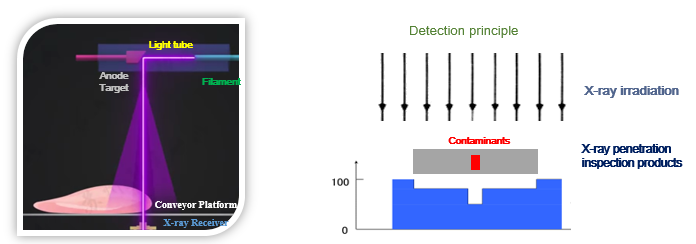

Principle of Techik X-ray Inspection system

X-rays have the property of penetrating objects. Under the condition of high voltage and low current, the cathode electron flow of the light source hits the anode tungsten target to produce X-rays, and through the slot at the bottom of the light source in the form of triangular projection, it is projected downward to the bottom light-sensitive component to obtain the irradiated image.

And through the slot at the bottom of the light source, in the form of triangular projection, downward projection, irradiation to the bottom light-sensitive components, then can obtain the irradiated image.

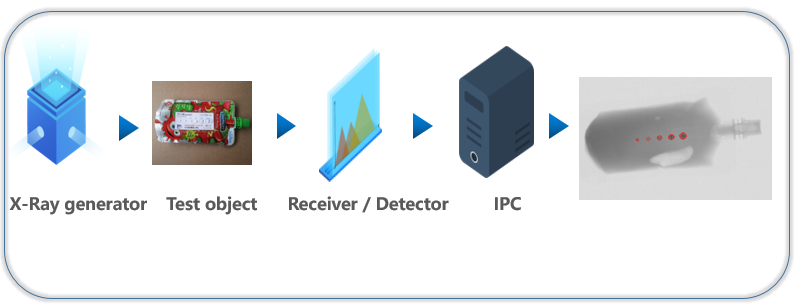

Key components of Techik X-ray Inspection system

How to choose generators for X-ray inspection system?

Mainly, beryllium window generator and glass window generator are usually used in Techik X-ray inspection system. Compared with beryllium window generator, glass window generator passes through three additional layers: 1.5-2mm glass wall, 2-10mm insulating oil, and 2mm resin window. Hence, beryllium generator can better preserve the low energy and is more suitable for dual energy detection.

Beryllium window 350W

Low-energy portion of the generator releases more light, allowing for clearer contours of low-density contaminants.

Advantage: clear imaging when detecting low-density contaminants. More clear when detecting organic impurities, bone products. More suitable for bulk materials, meat and other industries.

Disadvantage: When detecting uneven products, it is not very effective and possibility of false alarms will be raised.

Glass window 480W

Filter out part of the generator low-energy part, so that the emission of light biased towards the high energy level

Advantage: suitable for detection of mixed products, uneven products, detection of high-density contaminants imaging clear, when the detection of metal and stones and other foreign objects,possibility of false alarms low, adapt to a wide range of products.

Disadvantages: low-density contaminants are easy to be penetrated.

It is welcomed to send your products to our testing center to have a clear idea of what Techik inspection system can do. If you have the demand, send emails to sales@techik.net to book the free testing.